Table of Contents

Introduction

3D printing is an additive manufacturing technique that turns a digital design into a tangible object. It is described as an additive process because it simply stacks and fuses layers of material to create physical objects instead of using a block of material or a mold.

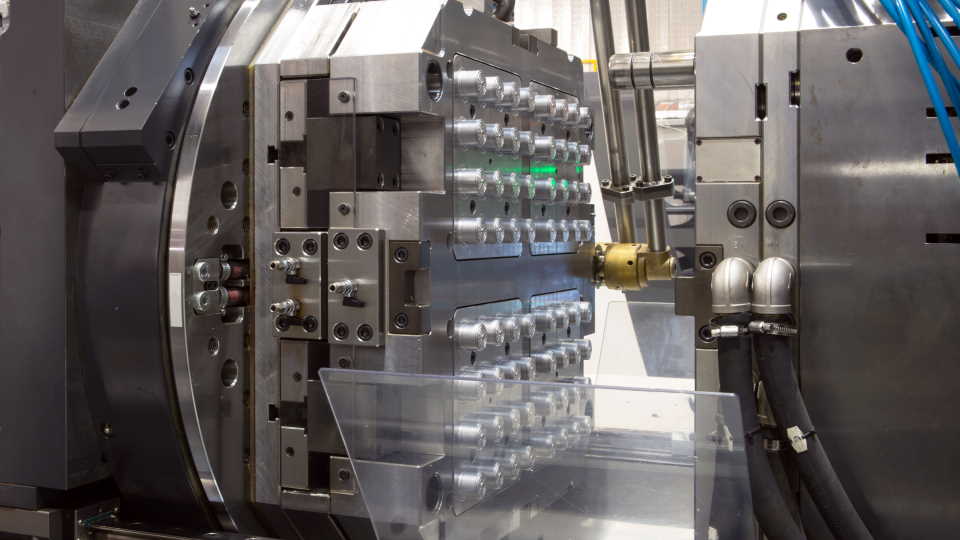

Injection molding is an entirely different process compared to 3D printing. Creating the mold itself is the first step. The majority of molds are constructed of metal, typically steel or aluminum, and are carefully machined to fit the characteristics of the product they are to manufacture.

Usually, injection molding is employed as a mass-production technique to create thousands of similar goods, unlike 3D printing, which focuses on creating detailed products, a few at a time.

Is 3D Printing Cheaper than Injection Molding?

3D printing can produce more complicated geometries than conventional technologies, is frequently quick, has cheap fixed setup costs, and has a growing array of materials.

The upfront cost of 3D printing is typically less than injection molding. The ability required to map the item in a CAD program is essentially the same, but 3D printing can print directly from the file. In contrast, injection molding has to make a mold or tooling before using the injection method to produce the part.

Compared to the material used by a 3D printer, an injected molded object requires substantially more experienced labor to operate the machinery but costs less to produce each part.

When determining the cost of production, you also need to consider the time spent during the process since time is money. 3D-printed objects can be made quite rapidly, but they can only be made in small batches, especially when compared to injection molding, which can make a significantly larger quantity of parts all at once.

Additionally, compared to 3D printing, injection molding has a far lower risk of part failure. Therefore parts produced that way are more likely to pass inspection, requiring less time to make the same number of parts.

Another aspect to consider is that with 3D printing, you may alter and update your design at any time during the manufacturing process. Because less time is needed on design, setup, and coordination with an injection molder, it also accelerates your time to market.

So when it comes to whether 3D printing is cheaper than injection molding, it is safe to say that it highly depends on your production load. If you make more than 100 components, injection molding is less expensive than 3D printing.

While the price per item for 3D printing remains broadly similar, the cost for injection molding substantially decreases as you produce more components using your mold.

Injection Molding vs. 3D Printing Cost

To determine how much an injection molding costs, you need to consider the cost of making a mold. Various crucial elements affect the cost of creating a specific mold for the desired items’ production.

The fundamental aspects to consider are the item’s dimensions, composition, and product’s level of complexity. These three elements have the most significant effects on the overall investment sum needed to construct a mold.

Injection molding and 3D printing processes differ significantly in terms of cost in one crucial area: price per unit. When employing an injection mold, the initial investment, or the actual production of the mold, accounts for the majority of the cost.

Your mold becomes more economical the more pieces it makes. The cost per item is remarkably stable while using 3D printers. The cost of the material and the amount of time required per unit are not affected by the manufacturing volume.

A mold and the first batch of injection-molded components may be more expensive to produce than 3D-printed parts, but when more parts are anticipated to be required, the price per unit cost will start to favor injection molding. After then, each subsequent order of parts will result in even more considerable savings.

Conclusion

In conclusion, if you wonder about the answer to is 3D printing cheaper than injection molding, 3D printing has certain financial advantages for prototyping and extremely short runs of ten to hundreds of pieces. Your risk and expenses are decreased.

This aspect might be priceless for start-ups that create opportunities that have never existed before. However, injection molding is the method of choice when creating a part for a large-scale, practical application with high-quality output that needs minimal finishing.

2 responses to “Is 3D Printing Cheaper than Injection Molding? Effective”

[…] The cost of injection molding is high for small-scale companies, compared to 3D printing. Designing the mold, including its precise cavity, costs money. However, injection molding becomes the more cost-effective alternative for high-volume production, such as 100 or more pieces. […]

[…] nozzles are fantastic for print quality. Standard brass nozzles work well for general-purpose 3D printing. At the same time, you need high-performance nozzles for abrasive […]